cotton

value

Chain

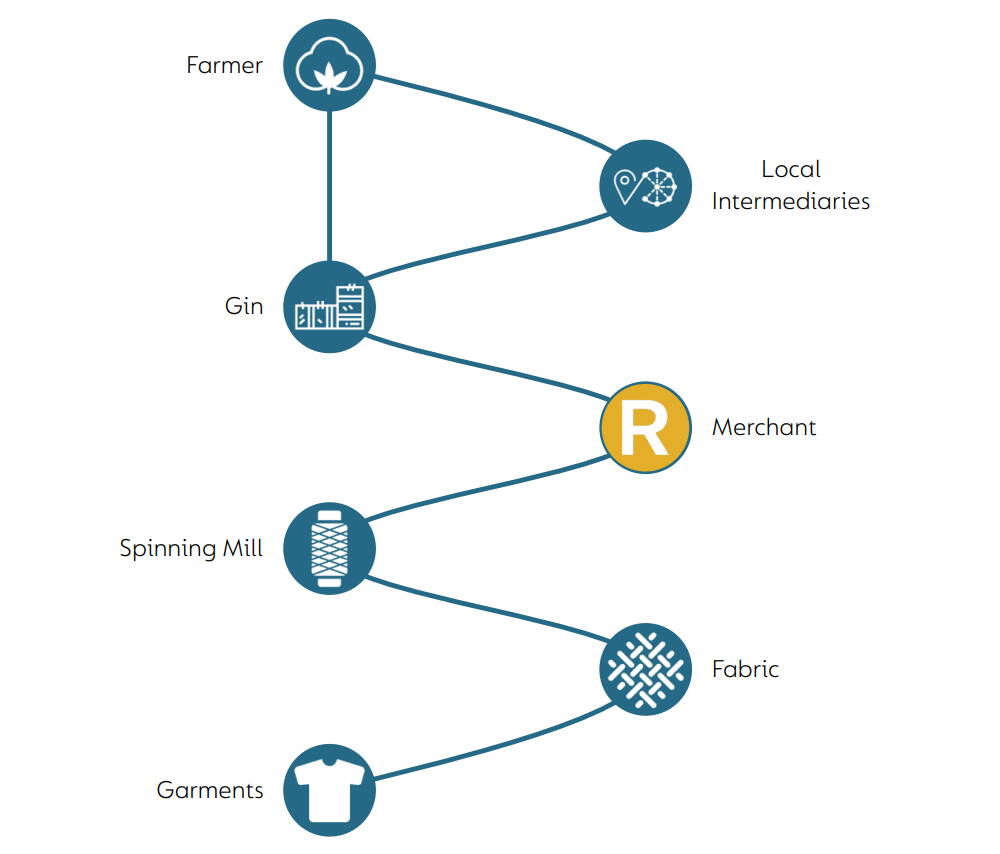

The cotton value chain is complex and long.

Learn about the individual steps along the cotton supply chain below.

From the grower...

Successful cultivation of cotton (Gossypium sp.), requires a long frost-free period of about 150 up to 200 days, plenty of sunshine, and a moderate rainfall. In general, these conditions are met within the seasonally dry tropics and subtropics in the Northern and Southern hemispheres. A large proportion of the cotton grown today is cultivated in areas with less rainfall that obtain the water from irrigation.

Cotton is grown in over 60 countries. About 90 percent is produced in the Northern Hemisphere and 10 percent in the Southern Hemisphere. Over 95 percent of cotton worldwide is of upland style, with a staple length between 1 inch and 1-5/32 of an inch. The balance is extra long staple cotton.

...to the gin...

After picking, the seed cotton is delivered to a gin. Here, the fiber is separated from the seed. Depending on weather, quality, seed variety as well as harvesting and ginning methods, between 35 and 40 percent of the weight of the seed cotton is cotton fiber, which is then compressed into bales of about 170 up to 380 kilos, depending on the origin. Cotton seed is used for cooking oil, animal feed and industrial purposes.

There are two types of ginning equipment: saw gins and roller gins. Saw gins are used mostly for upland cotton; because of their higher production capacity they are more economical to operate. Roller gins are considerably slower, but are gentler on the fiber; therefore they are commonly used for long staple cotton and also for some upland cottons in Turkey, East Africa and in parts of India.

...to the port...

Financing, transportation and storage are among the key functions of a cotton merchant, as cotton is not usually consumed at the place of its production.

More and more purchases are made on an ex-gin basis and the cotton is then classed and shipped to the port of destination. Today, many mills require “just-in-time” deliveries. The logistics involved are complex and require a high degree of experience.

...to the spinning mill

The spinning mill converts the cotton fiber into yarn which is used for weaving or knitting of fabric. The raw fabric goes through a number of finishing processes before being made into apparel, home furnishings and industrial products.

In spite of the challenges by manmade fibers, cotton kept its strong position among the textile fibers due to its special characteristics. It absorbs humidity well, it is not easily flammable, it holds up well in daily use, and it is not electrostatic. Most importantly, it is a product of nature and very comfortable to wear.